Global trade does not pause, but it does slow, sometimes sharply, when large parts of the world step away from work at the same time. Multi day public holiday periods can shift factory output, port handoffs, trucking capacity, banking settlement windows, and even how long a customs question sits in a queue. The tricky part is not that holidays exist, it is that their timing, length, and closure rules vary by country and by region, and those differences ripple across supply chains.

Key takeaway

The biggest disruptions happen when multi day public holidays overlap with manufacturing hubs, banking centers, and logistics corridors. Expect slower production, fewer vessel sailings, reduced customs staffing, and longer settlement timelines. The smartest teams plan around the closure pattern, not the holiday name: confirm local working days, pre book transport, buffer inventory, align payment cutoffs, and brief customers early. A reliable directory of country schedules makes this predictable instead of stressful.

Trade slows in predictable places

A shipping lane can stay open while the work behind it pauses. Containers can sit at a terminal because a warehouse team is out. A letter of credit can wait because banks are closed. A spare part can miss a flight because trucking capacity tightens. Multi day public holidays create these slowdowns by changing the number of hands available at each step.

The helpful mindset is simple: follow the handoffs. Trade has many of them, factory to forwarder, forwarder to port, port to vessel, vessel to destination terminal, terminal to truck, truck to warehouse, warehouse to customer. Each handoff can be delayed if one side is on holiday while the other side is working.

A short quiz to spot your risk level

Holiday impact quiz

Where multi day holidays hit global trade the hardest

Not every holiday has the same effect. A single day closure in one country may barely register. A week long pause across a manufacturing cluster, paired with reduced banking days, is a different story. Here are the pressure points that show up again and again.

- Factory and supplier output, production schedules compress before the break, then restart with a ramp up curve.

- Port and terminal operations, vessel windows stay fixed but yard moves and gate activity can slow if trucking and warehouse labor is thin.

- Customs and inspection, clearance often continues, but with smaller teams and longer response time for document checks.

- Domestic transport, trucking capacity can tighten around family travel peaks, and regional road restrictions can change.

- Banking and settlement, trade finance, payment releases, and reconciliation can pause in one market while another remains open.

- Buyer behavior, retail demand spikes before certain festivals, then dips, shifting order timing and promotional calendars.

Holiday slowdowns often look like a port problem, but they start earlier. A delayed supplier confirmation, a missed bank cutoff, or a missing inspection slot can add days before a container even reaches the gate.

The major multi day holiday periods that shape trade calendars

Every country has its own rhythm, but a few periods show up repeatedly in trade planning because they affect big networks of suppliers, carriers, and customers. The goal is not to memorize every holiday on earth. The goal is to know the periods that commonly create multi day closures and to verify the exact working days for the countries you rely on.

A practical way to do that is to keep a country based view of official dates, and check it against your shipping and payment cutoffs. If you need a starting point, public holidays worldwide can help you scan what is ahead and then drill into the countries you trade with.

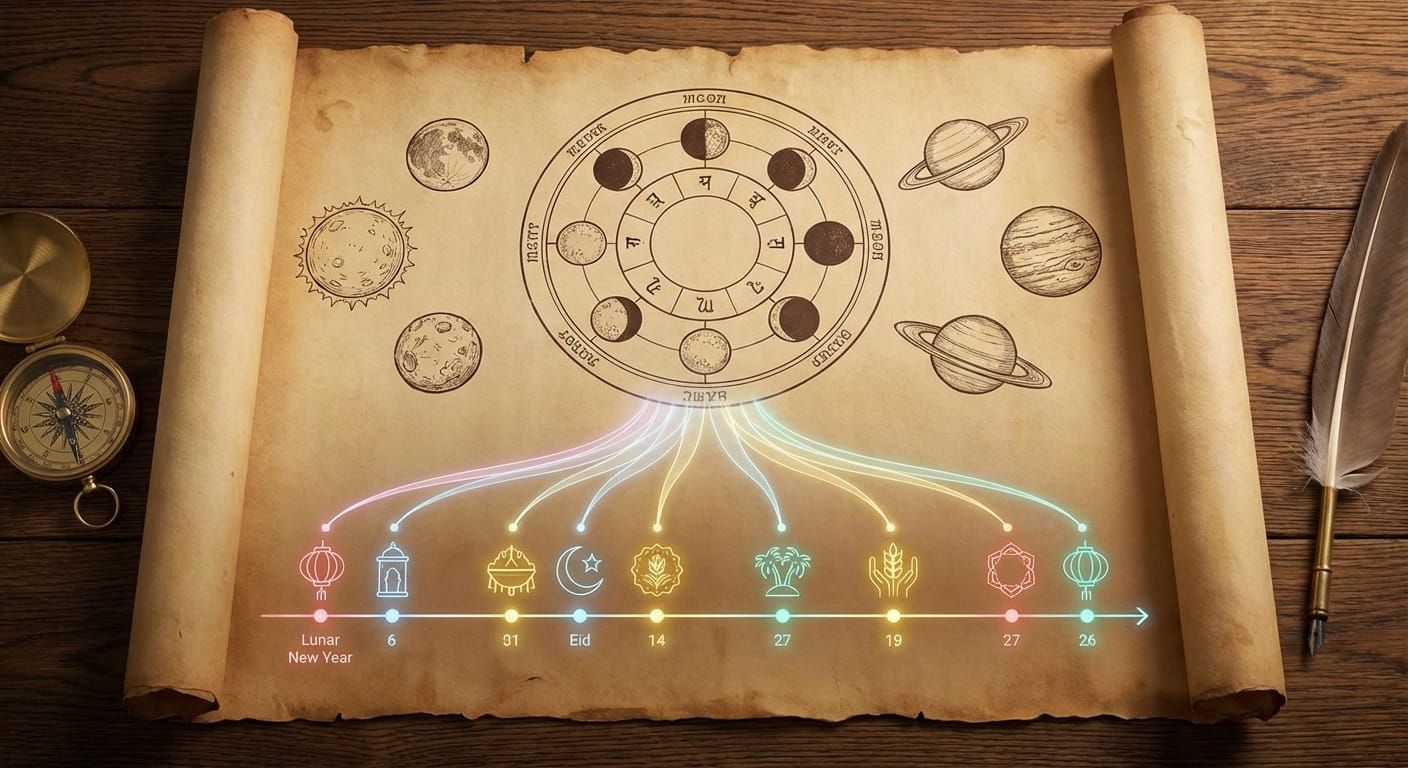

Lunar New Year period

Lunar New Year can be the largest planned pause in many East Asian supply chains. Factory closures vary by sector and region, and the official public holiday dates do not always reflect how long plants actually stop. Many businesses slow down earlier because workers travel, production lines finish batches, and suppliers stop accepting new orders.

Effects that often show up: container shortages in certain lanes, packed outbound schedules before the break, slower response times for engineering questions, and a gradual restart that can take weeks for full capacity.

Golden Week patterns

Some countries have clusters of holidays that create a week like pause. Even when only part of the economy shuts, travel demand can pull labor away from logistics roles. Export documentation can wait. Receiving teams can be thin. The lesson is that a named period can carry an informal slowdown that reaches beyond the official dates.

Spring religious festivals across multiple regions

Periods tied to spring observance, including Easter timing in parts of Europe and the Americas, can bring multi day closures. In some markets it is the banking and government side that quiets most. In others it is the warehouse and distribution side, driven by staff leave.

Eid periods

Eid holidays can mean several days of reduced business activity in parts of the Middle East, North Africa, and South Asia. Even where ports run, decision makers and signatories may be away. Plan for longer turnaround on document approvals, and confirm customs and inspection staffing with your broker.

Diwali and regional festival clusters

Multi day festival clusters can create staggered closures across states or provinces. That is when a single national view is not enough. A shipment might move through one state that is working and another that is not. If you manage India lanes, check the official dates for your corridors and facilities using India calendar holidays, then verify local practice with carriers and warehouses.

Year end period

The late December stretch is a trade classic. Even when only a few days are official holidays, many companies run with minimal staff. Some warehouses limit appointments. Some trucking providers operate reduced rosters. Many buyers also pull demand forward, creating congestion before the break and a softer patch right after.

A colorful map of impact, by trade function

This table is not meant to replace local verification. It is meant to make planning easier by linking holiday periods to the parts of trade they most often affect. Use it as a checklist, then confirm your specific lanes and facilities.

Why “public holiday” does not always mean “closed”

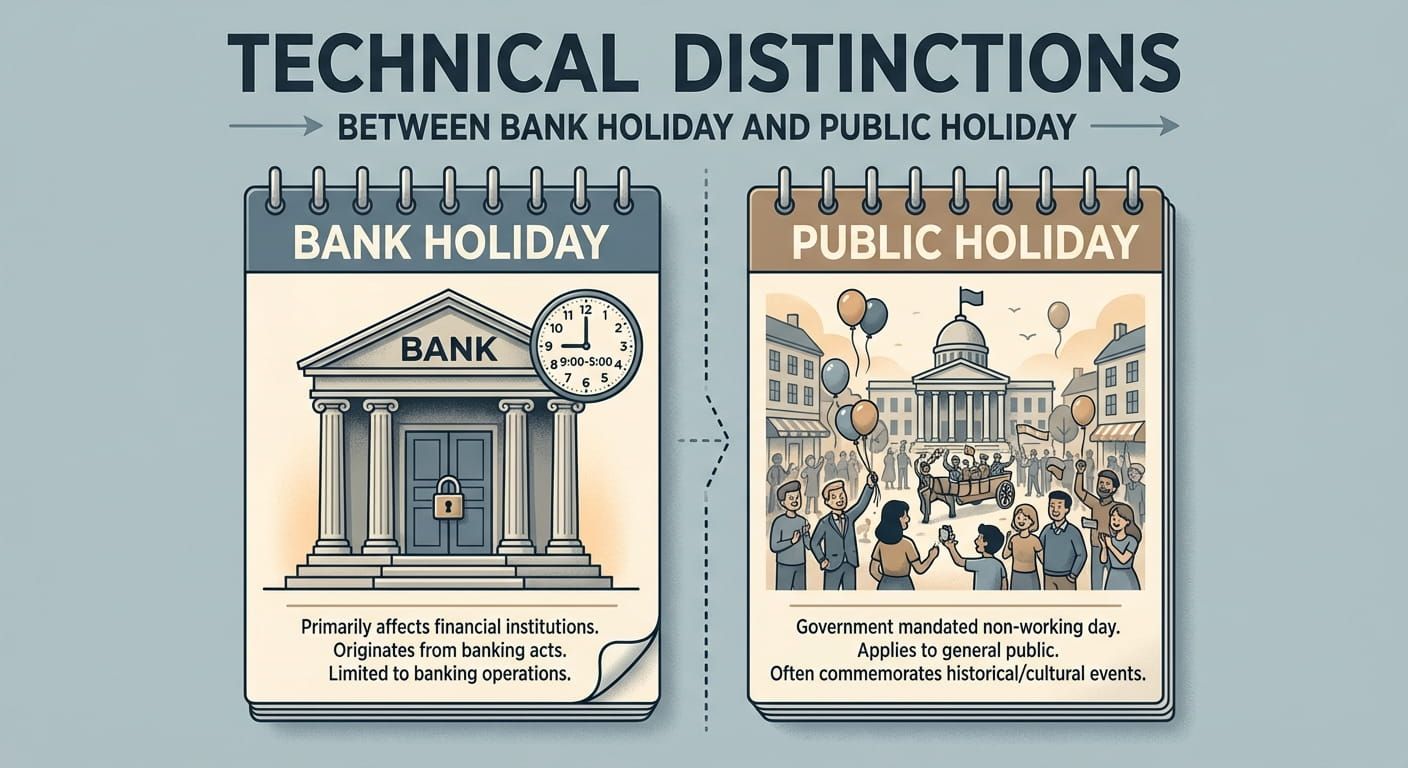

This is where teams get caught. A public holiday can mean a full shutdown for government offices but normal operations for private logistics firms. Or it can be the opposite: ports run, but the bank that releases your payment is closed. Even inside one country, some holidays apply nationally while others apply only to specific regions.

If your trade lane depends on bank processing, it helps to understand the difference between official public holidays and banking closures. bank holidays vs public holidays is a useful reference point for how these terms often differ, and why finance timing can diverge from warehouse timing.

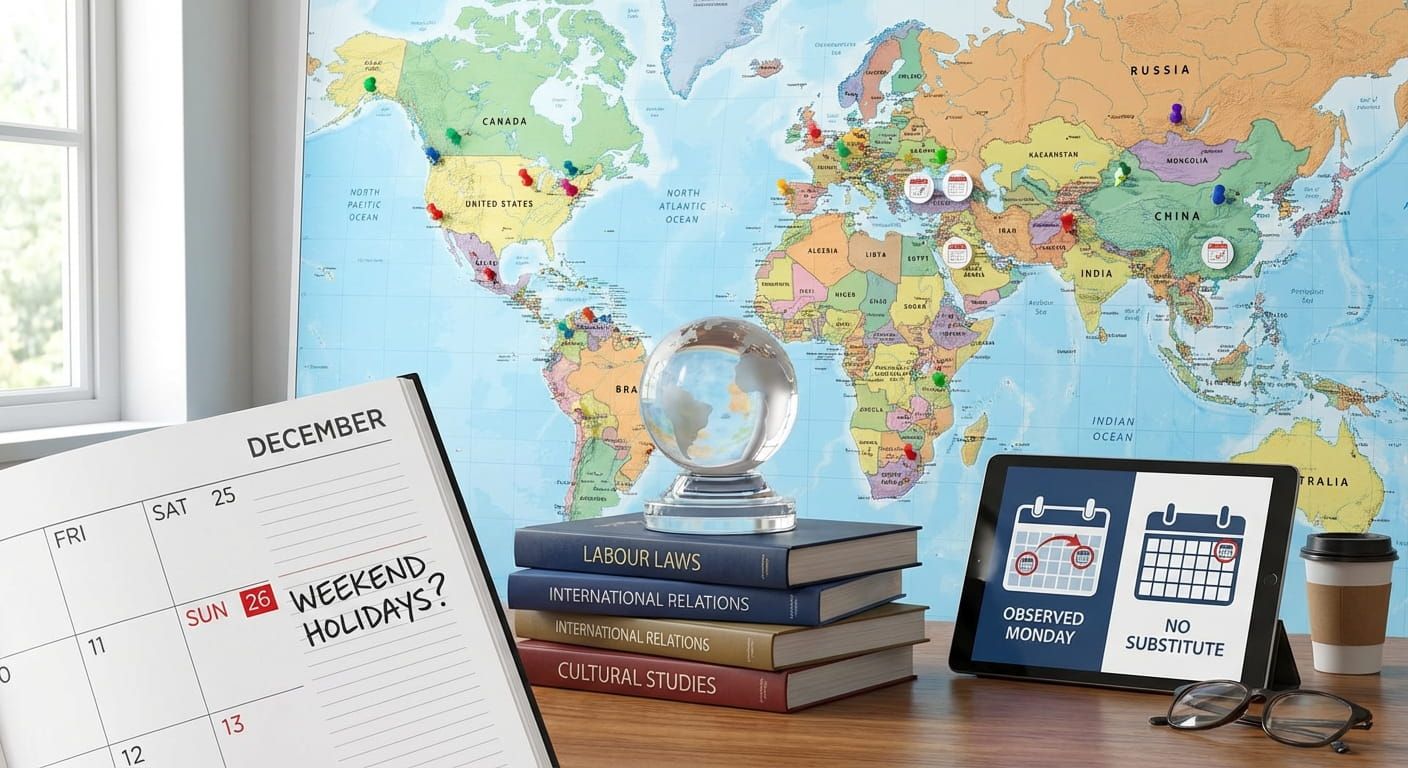

Weekend rules and substitution days can reshape a “short” holiday

Many calendars move an observed day off when a holiday lands on a weekend. That can turn a single date into a long weekend, changing pickup availability and customer receiving hours. It can also create an odd split where one office is closed on Friday while another closes on Monday.

If your planning relies on exact working days, review how substitution and observed day rules work in your markets. weekend public holiday rules explains the common patterns that influence what businesses actually do.

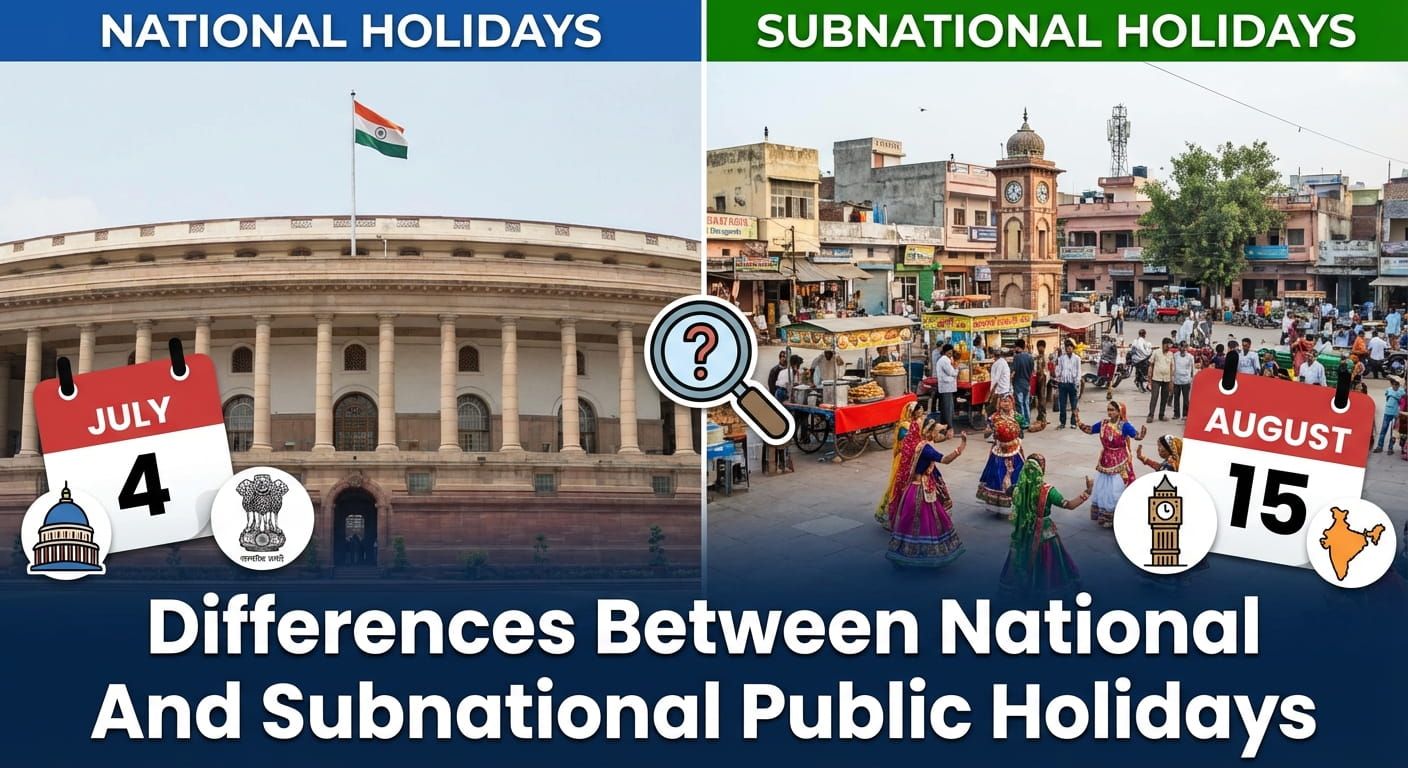

National and subnational dates can affect the same shipment differently

A truck can cross a provincial border and hit a different holiday. A distribution center might close while the head office stays open. A customs office in one city can run while another operates on reduced staffing. These are not edge cases, they are common in large countries and federations.

If you manage routes that cross internal regions, check whether your holiday is national or regional. National vs subnational public holidays can help you set up a process that respects those differences without turning planning into a full time job.

The real world mechanics behind holiday trade slowdowns

This section gets practical. Here are the mechanics that create the delays, and what they look like on a tracking screen.

Capacity pulls forward, then snaps back

Shippers try to move cargo before the break. That concentrates demand into fewer sailing dates and fewer trucking days. Rates can rise. Space can become scarce. Then the flow after the holiday can be uneven, because factories restart in waves and buyers reorder at different speeds.

Documentation queues lengthen

Even when operations continue, response time changes. A question about a packing list might wait longer. A correction to a certificate might sit in an inbox. A customs query can take extra days because the staff member who knows your file is away.

Last mile delivery feels the pinch

Drivers take leave. City congestion rises around travel peaks. Retail receiving teams shorten hours. For B2B deliveries, that increases failed delivery attempts and storage costs.

A holiday plan that only covers shipping dates misses the hidden delays. Put equal attention on paperwork, approvals, and receiving hours. Those are the places where “in transit” quietly becomes “waiting.”

A list you can use for every multi day holiday period

These steps work whether you are shipping apparel, electronics, spare parts, food, or industrial materials. They are written to be practical, with no fancy jargon, and you can hand them to a teammate without extra explanation.

- Identify the countries that touch your shipment, origin, transit, destination, and any key banking location.

- Confirm the local working days, do not assume a holiday name means the same thing everywhere.

- Lock critical dates, production finish, cargo ready, pickup, port cutoff, sailing, arrival, and delivery appointment.

- Move paperwork earlier than feels necessary, especially compliance docs, certificates, and trade finance forms.

- Build a buffer where you can afford it, inventory for key SKUs, time buffer for urgent lanes, or both.

- Pre book transport, space, trucks, and warehouse slots fill up before long breaks.

- Set customer expectations early, revised ETAs land better before an order is late.

- Plan the restart, confirm supplier ramp up dates and prioritize the first batches after reopening.

Country pages help teams stop guessing

Most trade mistakes around holidays happen for a simple reason: someone guessed. A calendar view that is country specific keeps planning grounded. For example, if a lane relies on European buyers and Southeast Asian suppliers, it helps to check dates for both ends, then look for overlap risk. Singapore calendar holidays can cover one side of that check, and Germany holidays can cover another.

The same approach works for major consumer markets. If your year end sales depend on US receiving schedules, reviewing United States calendar holidays alongside carrier cutoffs can reduce missed appointments and storage charges.

People problems are usually the biggest problem

Trade is run by people coordinating across time zones. Multi day holidays add a human reality: the person who approves your change request may be at a family gathering, and the person who books your truck may have a different holiday week than you do.

If you manage cross border teams, holiday planning is also a collaboration problem. managing cross border team schedules international public holidays offers a practical lens for keeping projects moving without burning out the people doing the work.

Public holiday closures can reshape travel and logistics

Holiday periods can bring travel surges, road rules, and limited service hours. That affects business travel, courier delivery, and time sensitive freight. If your shipments depend on receiving teams being present, or on airport and ground handling schedules, build those constraints into your plan.

For a grounded view of how closures and transport realities interact, public holiday closures travel logistics can help you connect the dots between a calendar date and a real logistics outcome.

How to talk to customers about holiday driven delays

A calm message beats a rushed apology. Customers do not need every operational detail, but they do need clarity. Two things help: naming the constraint and offering options.

Clear options usually look like this:

- Standard shipment with revised ETA and no extra cost.

- Expedite option with a price and a realistic delivery window.

- Partial ship option for urgent SKUs, with the rest following after reopening.

If you track how many holidays a market has, you can also set better expectations for lead times across the year. countries most public holidays can support that broader planning conversation without turning it into guesswork.

A simple habit that keeps holiday planning under control

Here is a habit that works for small businesses and large logistics teams alike: maintain a rolling view of the next thirty days for the countries you rely on, then run a weekly check against your shipment milestones. That is it. This prevents surprise closures and keeps your internal dates honest.

A directory built for this purpose makes the habit easy. It is also useful for travel planning and cultural context, because holiday timing is often tied to local customs and observances, not just government policy.

Turning multi day breaks into a planning advantage

Multi day public holidays will always exist, and that is a good thing. People rest. Communities gather. Traditions continue. Global trade can still run smoothly if teams respect the calendar, plan handoffs, and communicate early. The payoff is real: fewer surprise fees, fewer missed launches, steadier cash flow, and calmer relationships with partners.

The next time a long holiday period shows up on your lane, treat it as a known constraint, not a crisis. Check the right countries. Confirm the real working days. Move key actions earlier. Then let the rest of the world celebrate while your shipments keep moving on a plan you can trust.